The construction of KBA's new foundry hall in Wurzburg is bang on schedule

Scheduled for completion by the end of the year, the EURO14m (USD19.3m) project is one of the biggest KBA has implemented in recent years at its Wurzburg facility, and brings the total sum invested in new buildings there over the past ten years to well above EURO40m (USD55.1m). The investment reaffirms KBA's commitment both to its main production plant and to print. It also safeguards some highly skilled jobs at what is the biggest and oldest industrial enterprise in the region.

Speaking at the topping-out ceremony, deputy KBA president Claus Bolza-Schunemann called the EURO14m project proof of KBA's commitment to its Wurzburg production plant

1,339 cubic metres of concrete

In just six months a new shell was built around the existing 200m

(656ft) long production hall while production continued with virtually

no interruptions, and the old hall demolished. Special cranes were used

to position 235 concrete parts with millimetre precision. The outer

supports for two crane rails at different heights each weighed up to 51t

(56 US tons) and had to be inserted through the roof of the existing

hall.

In just six months a new shell was built around the existing 200m

(656ft) long production hall while production continued with virtually

no interruptions, and the old hall demolished. Special cranes were used

to position 235 concrete parts with millimetre precision. The outer

supports for two crane rails at different heights each weighed up to 51t

(56 US tons) and had to be inserted through the roof of the existing

hall.

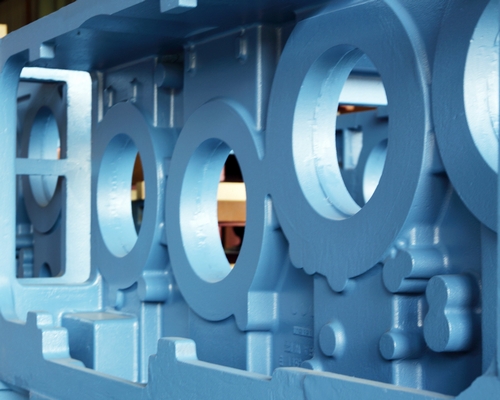

Following a complete overhaul and upgrade, the foundry at KBA's main plant can produce large press parts such as side frames and substructures much faster and more efficiently

High-powered infrastructure for foundry operation

The new hall with a crane capacity of up to 50t (55 US tons) is several

metres higher and some 50 per cent broader than the old hall. This will

enable it to produce large press parts such as side frames and

substructures much faster and more efficiently. It will also be able to

handle workpieces whose technological or metallurgical properties meant

that they previously had to be processed externally. These include

spherical cast iron, which alongside normal cast iron with flake

graphite is used increasingly for contract work. A large-core production

capability with two blenders will be added to the existing small-core

line. Materials flow and space utilisation will be optimised to allow

additional productivity-enhancing and cost-cutting potential to be

exploited and a larger number of workpieces to be processed.

The new hall with a crane capacity of up to 50t (55 US tons) is several

metres higher and some 50 per cent broader than the old hall. This will

enable it to produce large press parts such as side frames and

substructures much faster and more efficiently. It will also be able to

handle workpieces whose technological or metallurgical properties meant

that they previously had to be processed externally. These include

spherical cast iron, which alongside normal cast iron with flake

graphite is used increasingly for contract work. A large-core production

capability with two blenders will be added to the existing small-core

line. Materials flow and space utilisation will be optimised to allow

additional productivity-enhancing and cost-cutting potential to be

exploited and a larger number of workpieces to be processed.

Polisher Lothar Scholz from building contractors Koster performed the traditional topping-out ceremony

The new hall and equipment upgrade will not only improve the working environment for foundry staff, but also cut emissions, while heat recovery from the furnaces and sand-cooling plant will be expanded to enhance the energy credentials of the entire factory.

The ceremony was accompanied by the KBA band under Franz Beil

Source: KBA.com