1.3 – this is the average print run per (photo)book that Bubu produces in the short-run segment. In other words, for every two book-of-one orders, one is for two copies. Since 2004 – the year Bubu became the first Swiss company to bring design software for photobooks to market – these have been distributed under the label Bookfactory, which is among the leading providers of photobooks in Switzerland.

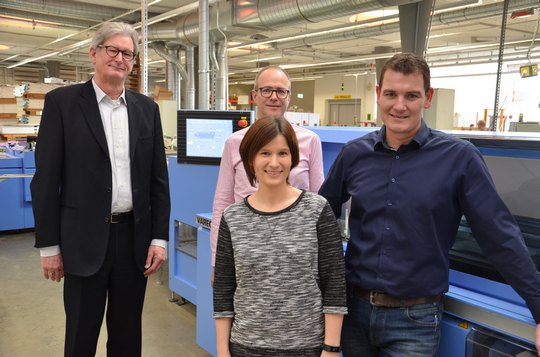

This gives Bubu AG, which was founded in 1941 by Albert Burkhardt and is now led by Christian Burkhardt, the third generation of the family to run the company, a decisive advantage: “While our competitors come from film development, we are in the binding industry,” says CEO Thomas Freitag. He then adds in the same breath: “We bind ideas, creativity and people. Photobooks are very emotional, and we believe there’s a future for haptic communication.”

Bookfactory, which specializes in digital production, allows Bubu to consistently follow its corporate philosophy – which is based on offset production: “It is not the book itself, but rather its finishing that makes the difference” (Thomas Freitag). That’s why, for example, Bubu prints black and white photos using duplex technology, frequently uses special paper and is known for its unique book covers.

A majority of the revenues earned by Bubu, which employs some 90 people, come from industrial bookbinding orders for printers, mainly in Switzerland. Bubu uses an Acoro A5 perfect binder, a Diamant 60 bookline with an endsheet feeder and a Collibri backgluing machine from Muller Martini for these orders. Bubu also produces photobooks for the company’s photobook portal bookfactory.ch, which has made a name for itself with its high-quality and diverse photobooks. And Bubu has once again ventured into new technological territory for these products – at least in the hardcover area.

As part of a field test, the family company is using a new integrated inline system with an endsheet feeder, a Vareo perfect binder and an InfiniTrim three-knife trimmer for the production of hardcover book blocks in runs of one. Muller Martini presented this inline solution to the wider public at the Hunkeler Innovationdays in Lucerne last February as a world premiere.

“We were looking for an all-in-one solution for hardcover books with runs of one and we didn’t make things easy on ourselves by looking closely at five different solutions,” says Raphael Kacimi. The CTO of Bubu said there were four main points in favor of Muller Martini’s equipment:

- The robust machine construction

- The proximity to the plant in Zofingen

- Their good experiences with the other machines

- The option of using them as a hybrid solution

The biggest challenge with photobook production is the variable product thickness of the books and the automated pre-gluing of the endsheets along with very short setup times. “This machine is like a chameleon – it can really do a lot,” says Raphael Kacimi. “It’s barcode-controlled, highly reliable and, thanks to its flexibility and broad range of formats, it allows us to produce a wide variety of creative book formats – from perfect-bound and thread-sewn softcover and hardcover books to special brochures, such as Swiss and layflat brochures.”

Commencing the pilot operation with Muller Martini was an exciting challenge for Thomas Freitag, one we were happy to accept. “We have always been interested in innovation. For example, we bought an Acoro from the pilot series in 2000. We enjoy working with competent partners to look to the future. This allows us to work together with machine manufacturers to create a common path for the future of the book.”While there were, as the CEO notes, “some gaffes here and there, you can’t stumble if you don't move forward, and the collaboration with our long-term partner Muller Martini was very constructive. And the equipment worked astonishingly well from the start.”

This was due in part to the valuable experience that Bubu has gained from working with the Collibri endsheet feeder for many years. But for Raphael Kacimi the highlight of the new integrated inline system is not the endsheet feeder, but rather the InfiniTrim three-knife trimmer: “I’m thrilled with its high trim quality and the fact that it doesn’t need any setup time – the InfiniTrim represents a quantum leap in three-knife trimmer technology.”

For Bubu, the quality of the end products is one of the key advantages of the feeder/VBA/Vareo/InfiniTrim system, which it uses for both digital and offset print products. Another advantage are lower staff and unit costs as well as shorter delivery times compared to the previous short-run solution, which involved various manual interventions. This is because the new machine can be operated by two people. “Our goal is 40 percent higher productivity,” says Thomas Freitag.