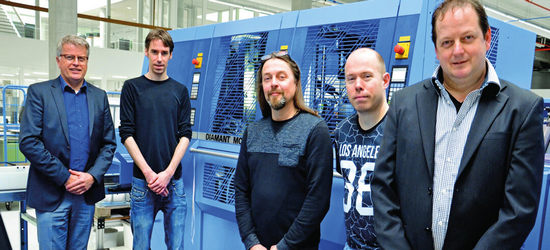

NBD Biblion is successful in three different segments of the graphic arts industry – the conversion of softcover into hardcover books for 900 libraries (mainly for libraries in the Netherlands, but also for a number of customers in Belgium), on-demand, in-house production of digitally printed books in short runs of right down to one copy, and the manufacturing of machines for specific print finishing processes. Let’s look at each of those segments in turn.

Library Books

NBD Biblion, which was established in 1970 as a joint venture of Dutch publishing companies and libraries, specializes in the preparation of hardcover books to meet libraries’ needs. To extend the durability of the books, which pass through the hands of many borrowers, a cleverly designed process is used to turn softcover books into hardcover books.

The covers are first removed from the softcover books, which are mainly supplied by publishing companies. The spines of the book blocks are then milled, re-glued with a cold dispersion glue, and mull is applied. Next, the new Diamant MC Digital Book of One, which was purchased at drupa 2016, comes into play together with a de-stacker that was developed by Biblion (see below). The book blocks are cased in and given a hard cover using the world’s first bookline of its kind (which we presented in the December 2016 edition of “Panorama”). The book spines are rounded and double backed, and the joint is formed.

In line with Muller Martini’s Finishing 4.0 philosophy, all those steps are performed fully automatically and touchlessly for some 2 million books each year. Once the data on a process slip have been scanned in, the Diamant MC Digital with a BLSD book stacker changes itself over for each job fully automatically. Currently, around 75 changeovers are performed each day. That is more than double as many as with the Diamant 60 used by the company between 2005 and 2016, which had to be changed over manually.

The Diamant MC Digital’s pressing unit, which has been adopted from the conventional Diamant, guarantees high book quality. “That’s one of our key USPs”, says Richard van der Voorn. “We give libraries a whole-year guarantee although the books are subject to particular wear owing to the many readers”.

The Diamant MC Digital at NBD Biblion frequently produces runs of one copy, with a maximum run size of 1,000 copies, whereas previously runs of below 25 copies were produced manually or semi-automatically using its predecessor, the Diamant 60. “That’s of key importance to us because there’s increasing demand for short hardcover runs”, says Richard van der Voorn. “In addition, we only need two instead of three people for the whole line, which has greatly increased our cost-effectiveness”.

The Technical Team Manager has ambitious plans for the bookline, which ensures the optimal cost-effectiveness of short runs. Soon 150 changeovers are to be performed daily, representing an increase of 500 percent compared to the previous solution.

Book on Demand

The new Diamant MC Digital is also set to boost a second segment at NBD Biblion – book on demand. The company, which uses two digital printing systems and has a sophisticated, highly automated logistics system, has been active in that segment for four years. Richard van der Voorn sees great potential for growth in that field, which is why an Account Manager was hired specifically for the on-demand segment in the past year. Novels, manuals and academic works are produced for publishing companies, businesses and self-publishers in runs of one to 2,000 copies, with an average run size of 35 to 50 copies per title.

Machine Manufacturing

There is also a direct link between the Diamant MC Digital and NBD Biblion’s third main segment, namely machine manufacturing. The innovative company, which employs 160 people, has acquired a strong reputation in recent years for the specialist print finishing machines that it develops itself. Its de-stacker, for instance, ensures that the converted single-copy book blocks enter the bookline in single-cycle mode. In addition to the de-stacker – thanks to which one less operator is needed for the hardcover line – NBD Biblion uses a dozen or more other machines that it has manufactured itself for additional process steps, such as film wrapping of the cover to improve the durability of each book, the application of a classmark label to the book spine, and the application of the content description and RFID chip to the inside of the book cover. NBD is increasingly successful in selling such machines to printing plants, bookbinderies, photo book producers and libraries all over the world.